Swiss Solar way: into the future with new technologies

20/10/2021

Annual expenditures on research in solar energy worldwide amount to billions of dollars. Their share in the total volume of investment in solar energy, which in the previous decade 2010-2019 alone amounted to $1.3 trillion, is quite significant. As almost half a century of history shows, it is the latest discoveries, developments and technologies that the photovoltaic (PV) industry owes its birth and rapid development to.

Today, hundreds of organizations, companies and thousands of researchers around the world contribute to R&D in the field of solar energy. Among them are the largest state and international organizations – National Renewable Energy Laboratory (NREL), Chinese Academy of Sciences, research institutes – Fraunhofer Institute for Solar Energy Systems (ISE), Helmholtz Zentrum Berlin, private companies – Oxford PV (Great Britain), Microquanta Semiconductor (China), Solaronix SA (Switzerland).

Since its foundation, Swiss Solar has based its development strategy on the use of innovative technologies. Over the past 2 years, more than 40 million Swiss francs have been invested in the development of new high-efficiency solar modules. Not limited to investing in their own development, the company regularly monitors research and advances in the development of new materials, technologies and ideas for the solar industry. This allows the company’s management to confidently choose the direction of development, and specialists – to create new, more efficient types of solar modules for their customers.

In this short review, we will discuss which materials, technologies and original technical solutions, according to our experts, have the greatest potential and can have a serious impact on the PV-systems-market in the next decade.

Materials

It is safe to say that since the creation of the first PV cells, the entire history of the PV-industry is a history of searching, researching and synthesizing materials that ensure their maximum performance. And since this goal has not yet been achieved, the search continues.

Among all the materials for solar panels created over the past decade, let’s single out and consider the perovskite group as the most promising in terms of commercial use.

Perovskites

Known since the middle of the 19th century as a source of titanium, niobium, and some other elements, perovskite has become widely recognized only in recent decades. The study of its crystal lattice structure allowed scientists to obtain a number of compounds (oxides, halides, etc.) with a similar structure or its derivative, which received the common name – perovskites. As it turned out, introducing certain changes in their crystal structure in the process of synthesis makes it possible to obtain semiconductor materials that can be used in the production of solar cells.

Research and numerous experiments have shown the high efficiency of solar modules built on cells made of synthesized perovskite crystals. Among other new solar materials (organic PV-cells, dye-sensitized solar cells) they stand out for their high ability to absorb solar energy.

An important advantage of perovskite solar cells is the wide spectrum of solar energy absorption. Changing the chemical structure of perovskites (replacing the atoms in the crystal lattice) makes it possible to obtain materials that are more sensitive to a certain part of the spectrum, which greatly increases the efficiency of PV cells. To understand the importance of this fact, let’s just say that traditional silicon cells convert only a small part of the sunlight from the red part of the spectrum into electricity, the rest of the radiation remains unused.

Current production technologies make it possible to obtain perovskites in the form of solutions and apply them in a very thin layer using the following methods:

- solution drying;

- centrifugation;

- inkjet printing.

The resulting materials have a polycrystalline structure and are tolerant of even a large number of defects in the crystal structure, unlike monocrystalline silicon cells.

This reduces the cost of production, makes material application to surfaces of almost any geometric shape available, and simplifies the creation of flexible photovoltaic cells. The low level of production costs (compared to silicon PV-cells) is also explained be the lower energy intensity of the processes, the lack of the need for high purity production facilities and the use of vacuum chambers.

At the same time, despite significant progress in efficiency (as late as 2019, perovskite PV-cells reached 25.2%), the stability of cells made of these materials remains a serious problem. The ease of fabrication has so far been negated by the critically low resistance to oxygen and humidity. The stable operation duration of several tens of thousands of hours achieved so far suggests that they still have a long way to go before they reach a lifetime of 25-30 years (like silicon cells).

The search in this direction is ongoing, and the available solutions give confidence in achieving the goal soon. In Australia, for example, scientists have already achieved a dramatic improvement in resistance by using a low-cost polymer glass coating as protection. The samples they provided were tested for compliance with IEC 61215:2016, withstanding 75 days of heat tests and 75 freeze cycles (at temperatures from -40 to +85 and 85% relative humidity). [1]

Today, perovskites are making only their first steps on the market, and the prospects for their commercial use are still far from silicon PV-cells. However, as investment in research grows, production capacity expands, and stability issues are resolved, their market share will grow steadily.

Technology

The development of new technologies for manufacturing PV-cells is another direction in the search for ways to improve the efficiency of solar panels. Today, scientists are conducting research and experiments in several directions. The specialists of Swiss Solar consider the most promising technologies:

- tandem solar cells;

- colloidal quantum dots.

Let’s take a closer look at the fundamental differences, advantages and disadvantages of each of them.

Multi-junction (tandem, multilayer) solar cells

The main factor that stimulated the research and eventually led to the creation of cells of this type was the discovery by William Shockley and Hans-Joachim Queisser of the efficiency limit of single-junction solar cells, made in 1961. The calculations made by the scientists showed that the existence of the limit is related to the lack of physical ability of solar cells of this type to effectively absorb the entire spectrum of solar radiation. This allowed the researchers to define the direction of their research as the search for opportunities to expand the absorption spectrum of solar cells.

The solution found is based on the creation of a cascade effect that occurs when light passes through two or more layers of photovoltaic materials overlapping each other. Each layer converts light waves of a specific wavelength into electricity, which ensures a fuller use of solar radiation.

Today, there is a fairly large number of intensively developing PV-technologies for creating multi-junction solar cells. According to the classification proposed by the International Renewable Energy Agency (IRENA) [2], they can be grouped by the type of materials used:

Organic

They are made of conductive organic polymers. Their advantages include:

- high optical absorption coefficient;

- relative transparency;

- possibility of adjusting the band gap width;

- low manufacturing costs.

At the same time the maximum efficiency does not exceed 10-15%.

Inorganic

Manufactured from materials of groups III-V of the periodic table (Ga, In, As, P). They are characterized by:

- high conversion efficiency;

- possibility of tuning of band gap width;

- lower loss of efficiency at heating (in comparison with Si).

A combination of these properties has already produced cells with an efficiency up to 44.4% for cells with three transitions (GaInP / InGaAs / InGaAs) and 46% for cells with four transitions (GaInP / GaAs / GaInAsP / GaInAsAs).

A significant disadvantage of such cells is a very high cost of their production, which even with such a high efficiency limits their use to space programs so far.

Hybrid

The most promising type of cells for commercial use.

Cells created using this technology contain layers of different materials that form multiple p-n junctions. The ideal solar cell, in theory, should have hundreds of different layers (p-n junctions), each tuned to a small range of light wavelengths across the spectrum, from ultraviolet to infrared.

Creating tandems based on the most common silicon cells in the PV industry today allows not only to overcome the already mentioned Shockley-Queisser limit, but also to obtain more efficient and inexpensive PV solar cells.

Thus, applying a semitransparent layer of perovskite to the surface of silicon cells allows for a cascade effect. Tuned to absorb light waves of a certain wavelength, perovskite allows the rest of the radiation to pass through, making it available for absorption by the silicon layer. This allows tandem cells to use solar radiation more efficiently and achieve higher performance.

Researchers believe that such a solution will make it possible to combine the technological advantages of perovskites with the developed production infrastructure of silicon cells in the future. Oxford scientist Henry Snaith is confident that tandem cells made of silicon and perovskites will become widespread commercially within the next 10 years. [3]

At the same time, despite the presence of significant advantages, multilayer solar cells are not yet free from drawbacks. The main ones are:

- the problem of layer compatibility: each layer, starting from the top, must absorb light of its own wavelength and not interfere with the passage of other waves to the lower layers, also to obtain maximum power requires electrical coordination, since the operating voltages and currents of the layers may differ;

- lack of well-established manufacturing technology: the materials of the layers should be combined the way that an application of each subsequent layer does not violate the structure of the previous one;

- durability: in order to create a high-quality multilayer-element, all of its layers must have the same durability;

- cost-effectiveness of mass production: besides increased efficiency, tandem cells should successfully withstand competition in price with the most widespread silicon cells.

Colloidal quantum dots

Quantum dots (QDs) are semiconductor nanocrystals (less than 10nm in size) whose electronic and optical properties differ significantly from massive semiconductors. This is due to the fact that with such small crystal sizes, comparable to the de-Broglie-wavelength, the processes occurring in them during light absorption take on a quantum nature. The unique properties of quantum dots are:

- ability to adjust the absorption spectrum by selecting the size of nanocrystals;

- ability to absorb light both in the visible part of the spectrum and in the near infrared range;

- high extinction coefficients (a measure of the efficiency of light absorption of a given wavelength).

These features drive the interest in their use in the solar power industry.

The first PV cells created on the basis of quantum dots back in 1998 had a low (about 1%) efficiency, [4] and the precision method of their production developed by that time – molecular-beam epitaxy – turned out to be very expensive. However, active research and experiments in this field (more than 50,000 papers published in the last 10 years alone) allowed significant progress to be made.

Already by 2017, the efficiency of PV-elements on QDs had increased to 13.4%, and the development of the method of high-temperature colloidal synthesis [5] allowed not only to obtain new colloidal quantum dots (CQDs), but also to make the technology of their synthesis simple and cheap.

Due to the convenience of the chemical production method and the small thickness of the coating, quantum dots can be used as a top transparent layer as well as implemented in hybrid solar cells. The creating tandems with silicon solar cells can have a positive effect on their performance and cost.

The most promising to date is the research and development based on:

- lead chalcogenide quantum dots (PbX, X=S, Se);

- carbon quantum dots;

- lead halide perovskite quantum dots (perovskite nanocrystals).

All of them are characterized by outstanding optoelectronic properties, energy conversion efficiency, ease of synthesis, and stability.

Concentrating Photovoltaic

Among the technical solutions that allow to achieve a significant increase in the performance of solar cells, we should mention Concentrating Photovoltaic (CPV) systems and applications, which currently show the best results in terms of solar energy conversion efficiency. The idea of using sunlight concentrated via optical lenses to increase the output of solar cells originated and was implemented back in the days when their cost was high and the developers were faced with the task of getting the maximum output from a minimum-sized cell.

Further development and improvement of CPV efficiency followed several directions:

- use of solar trackers;

- search for lighter and stronger lens materials;

- using a cooling system;

- replacing silicon cells with more efficient multi-junction cells.

Insolight Technology

One of the latest achievements in the field of CPV applications is the development of the Swiss company Insolight, which can already be referred to as the new generation of high concentration PV (HCPV). The solution presented by the team of young scientists is radically different from the existing concentration modules, which are large-scale constructions of lenses, mirrors and electric drives that adjust their position depending of the position of the sun. Hexagonal lenses located directly in the protective glass of the innovative module simultaneously solve two tasks: concentrate the light flux and follow the changes in the position of the sun.

The semi-transparent version of the module developed by the company transmits enough light for growing plants, which allows them to be used to cover greenhouses and opens up the possibility of installing solar power plants on agricultural land without taking it out of circulation. Both investors and farmers will benefit from this application – the former by saving on the purchase of land, the latter by being able to continue growing agricultural products.

Conclusion

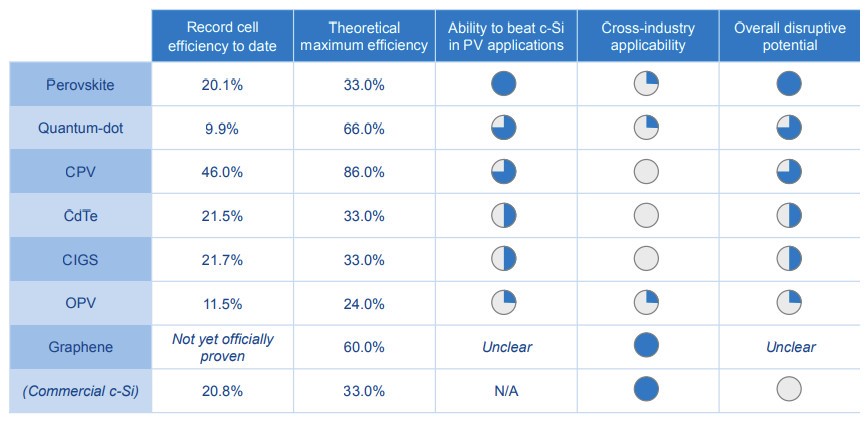

As a conclusion, let us make a comparative assessment of the “breakthrough” potential of entering the PV-market, both the materials, technologies and technical solutions already considered, and those that remain outside the scope of this article (Table 1). As we can see, these estimates agree well with the choice we made.

Tab. 1 Short-listed emerging PV technologies and their disruptive potential [6]

We should also note that the brief overview certainly does not claim to be complete and does not guarantee the fulfillment of forecasts 100%. However, it is enough to make an unambiguous conclusion that the era of silicon solar modules in the PV market is coming to an end.

References

[3] https://www.nbcnews.com/science/environment/solar-panels-are-reaching-limit-crystals-change-rcna545

[4] Zaban A. et al. Photosensitization of Nanoporous TiO2Electrodes with.pdf. 1998. Vol. 7463, № 11. P. 3153–3156.

[5] C.B.Murray, D.J.Norris, M.G.Bawendi. J. Am. Chem. Soc., 115, 8706 (1993)